Red Rock Mechanical, LLC

📍 Address: 339 Red Rock Rd, Colchester, VT 05446, USA

📞 Phone: +1 802-893-9992

🌐 Website: https://www.redrockmechanical.net/

★★★★★

Rating:3.9

The Essential Guide for Vermont Homeowners: Expert Insights from Red Rock Mechanical

When July humidity grips Northern Vermont or January lows turn pipes frosty, few systems in your home work harder or more quietly than your HVAC equipment. Yet, behind the comfort of a cool living room or a toasty bedroom lies a scientifically elegant process that many homeowners only notice when something goes wrong. Red Rock Mechanical, LLC—a family-owned, trusted fixture in Burlington and Colchester for over two decades—has earned a reputation not just for fixing and installing HVAC systems but for clearly explaining their inner workings. As certified, highly skilled technicians, their day-to-day experiences diagnosing air conditioners, heat pumps, and refrigeration units make them ideal guides in demystifying the refrigeration cycle.

In a region where seasonal extremes push home comfort systems to the limit, understanding the fundamentals of the refrigeration cycle isn’t just interesting background—it’s empowering. Whether your heat pump is icing up or the central air can’t keep pace, Red Rock Mechanical’s technicians have seen the full range of issues that stem from minor blips in this process. Leveraging years of hands-on troubleshooting, they excel at uncovering not only what’s wrong but why it happens, translating technical explanations into language any homeowner can grasp. With their expertise woven throughout, this deep dive aims to shed light on how this vital process works, why proper care matters, and what Vermont homeowners should know to keep their homes reliably comfortable year-round.

Demystifying the Refrigeration Cycle: The Science Keeping Your Home Comfortable

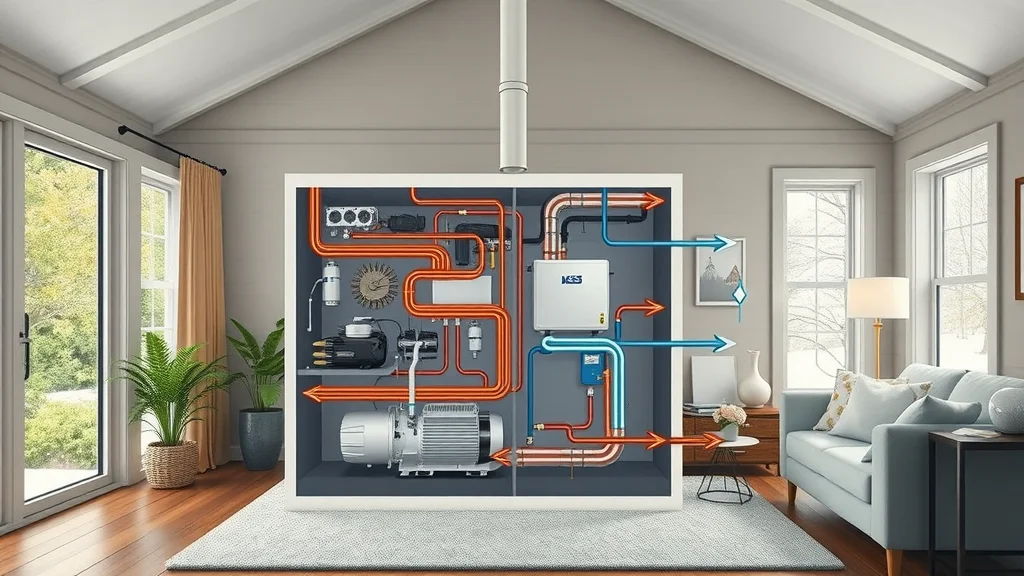

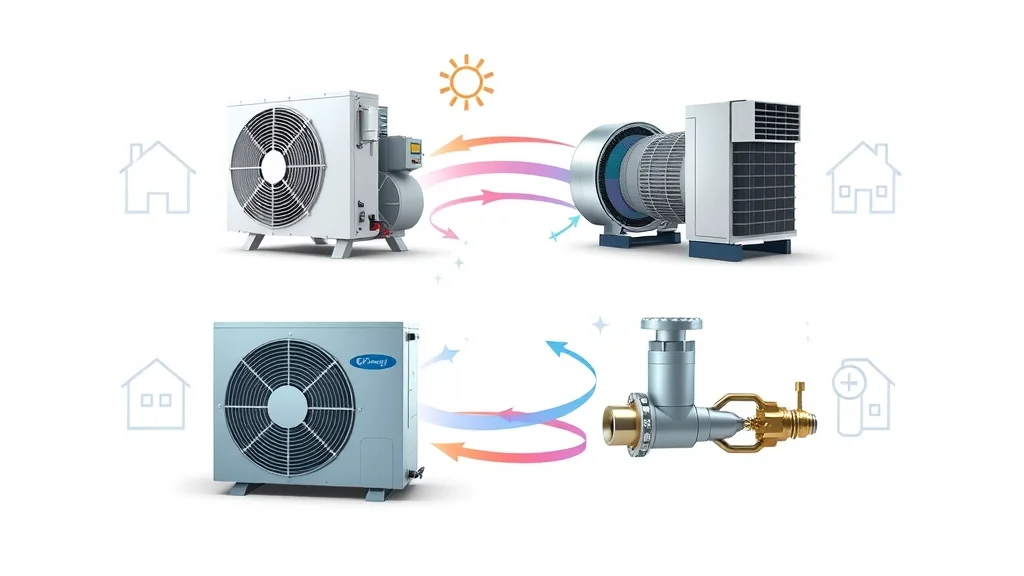

At the heart of every air conditioner and heat pump is a process both surprisingly simple and beautifully complex: the refrigeration cycle. This four-step method—evaporation, compression, condensation, and expansion—relies on a special fluid called refrigerant that absorbs heat inside your home and releases it outdoors. The critical components guiding each stage are the evaporator, compressor, condenser, and expansion device, working in tandem to move heat from where it’s not wanted to where it’s harmless. As Red Rock Mechanical routinely explains to curious Vermont homeowners, understanding how each component functions can be the difference between simple maintenance and weeks of mounting frustration.

During operation, refrigerant is forced to change pressure and state—from low-pressure vapor to high-pressure liquid and back again. This shift is far from trivial: it’s what actually produces the cooling (or heating) effect you cherish on a muggy summer afternoon or a biting winter twilight. The system’s ability to efficiently move heat hinges on precise pressure changes, correct refrigerant charge, and seamless airflow—all factors Red Rock Mechanical’s technicians are trained to assess and correct. When these variables slip out of alignment, home comfort suffers, often revealing itself through tell-tale symptoms like ice buildup, uneven temperatures, or short cycling. For Vermont homeowners unfamiliar with these nuances, the workings of the refrigeration cycle might seem opaque, but knowing what to look for—and when to call a professional—can make all the difference.

Why Mastering the Refrigeration Cycle Matters for Homeowners

When daily comfort is interrupted—whether by a muggy bedroom, persistent ice on the heat pump, or unexplained warm air from the AC—homeowners often feel at a loss. That’s precisely when Red Rock Mechanical’s extensive expertise truly shines. Their NATE-certified technicians are adept at pinpointing where the refrigeration cycle falters and why, drawing from decades of field experience in the Burlington and Colchester regions. By methodically checking refrigerant levels, cleaning coils, and verifying component function, they translate mechanical mysteries into understandable fixes, never hesitating to educate homeowners along the way.

Symptoms like low air output or persistent system cycling usually track back to imbalances in core factors: refrigerant charge, airflow, or equipment cleanliness. Through systematic inspection and using diagnostic tools, Red Rock Mechanical’s team pinpoints issues that can go unnoticed—restrictions in the expansion device, clogged air filters, or subtle leaks. This informed approach not only restores immediate comfort but also ensures homeowners understand what went wrong and how it can be prevented in the future. Such clarity is invaluable when navigating Vermont’s temperature swings, where an efficiently running HVAC system makes all the difference between a cozy, peaceful home and a season of discomfort.

Getting to Know the Four Essential Components of Your HVAC System

For the refrigeration cycle to function at peak efficiency, each major part must do its job seamlessly. The evaporator absorbs heat from your indoor air, cooling it down as refrigerant within the coil changes from a liquid to a vapor. Next, the compressor—often called the heart of the system—pressurizes the vapor, raising both its temperature and pressure, before sending it along to the condenser outside. The condenser releases the absorbed heat outdoors as the refrigerant returns to a liquid state, while the expansion device—often a small but critical valve—meters the liquid refrigerant back into the evaporator, starting the cycle anew. Red Rock Mechanical’s experienced technicians frequently walk Vermont homeowners through these steps, highlighting that the cycle’s efficiency depends on every component performing perfectly and in sync.

Issues can appear at any stage: a clogged expansion device can restrict refrigerant flow, while a dirty condenser might block heat from escaping. Red Rock Mechanical’s method of troubleshooting involves not just visual inspection but detailed readings of temperature, pressure, and airflow, ensuring no weak link is left unaddressed. By fostering homeowner understanding of these components and their purpose, the team encourages proactive maintenance and early identification of common problems, saving clients time, money, and potential discomfort.

How Pressure Creates Comfort: The Role of Superheat, Subcooling, and Balanced Airflow

It’s the deliberate manipulation of pressure that allows refrigerant to work its magic. When Red Rock Mechanical trains homeowners on HVAC best practices, they demystify critical concepts like superheat and subcooling—temperature measurements that reveal whether the system is absorbing and releasing heat at the right spots. Too much or too little superheat indicates improper refrigerant flow, potentially caused by a dirty filter, a malfunctioning expansion device, or low refrigerant. These nuances, which technicians routinely check using specialized gauges, are essential for diagnosing issues before they morph into more significant system failures.

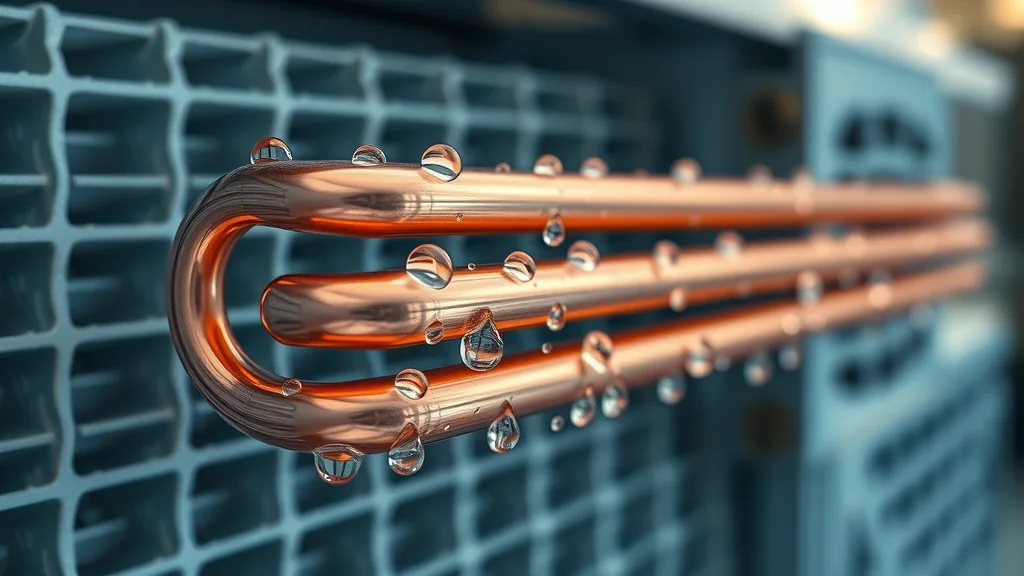

Balanced airflow, clean coils, and precisely charged refrigerant ensure the entire cycle hums along efficiently. If airflow is blocked—by a dirty filter, for example—the evaporator coil can freeze, starving your home of cold air. Conversely, a low refrigerant charge may cause the heat pump or AC to run longer, consuming more energy and struggling to achieve set temperatures. Red Rock Mechanical’s team stresses the importance of regular system cleaning, accurate refrigerant levels, and timely filter changes—practices that any attentive homeowner can embrace as part of a routine maintenance regime.

Recognizing the Warning Signs: What Homeowners Should Watch For

One of the most valuable lessons Red Rock Mechanical shares with their Vermont customers is how subtle changes can signal deeper issues within the refrigeration cycle. Ice accumulation on coils, sudden short cycling of the system, or a gradual increase in energy bills are classic early warning signs. Through years of emergency repairs and routine service calls, the Red Rock Mechanical team has cataloged these symptoms, helping homeowners to recognize when an issue is minor—and DIY safe—or when it’s time to call a professional.

Uneven cooling, unexplained noises, or persistent humidity despite a running system all hint at possible disruptions, whether due to airflow restrictions, incorrect refrigerant charge, or component wear. By providing homeowners with clear checklists and easy-to-understand diagnostics, Red Rock Mechanical empowers clients to take preventive action, ensuring Burlington and Colchester homes stay safe, efficient, and comfortable—all year round.

Red Rock Mechanical’s Thoughtful Approach: Precision, Education, and Preventive Care

With over two decades of service in Northwest Vermont, Red Rock Mechanical has long prioritized technical excellence, transparency, and homeowner education at every jobsite. Their approach to diagnosing refrigeration cycle issues blends industry certifications with a genuine commitment to customer clarity—taking time to walk through findings, explain the science, and discuss practical next steps rather than just fixing and leaving. Ongoing training keeps their team current on the latest technology, from energy-efficient heat pumps to dual fuel and central AC systems, ensuring recommendations are both effective and future-focused.

Preventive care is central to Red Rock Mechanical’s philosophy. By actively promoting regular inspections and cleaning, alongside timely filter changes and early issue detection, their technicians help extend the life of HVAC equipment and maintain high efficiency. Their practice of treating every call as a partnership, not just a transaction, has built a loyal base of Vermont homeowners who value honest guidance and lasting solutions. In an industry where attention to detail often determines comfort and safety, Red Rock Mechanical’s technical expertise and educational focus truly set them apart.

What Real Homeowners Say About Gaining HVAC Clarity with Red Rock Mechanical

Understanding home systems often begins with a crisis, but ends with newfound confidence—and thanks to Red Rock Mechanical’s approach, many local residents have become much savvier about how their comfort is maintained. Here is what one satisfied customer had to say after a service visit clarified a puzzling cooling problem:

“Red Rock Mechanical quickly found a restriction in our system’s expansion valve. They explained the refrigeration cycle so clearly that we finally understood why the house never cooled evenly.”

Genuine, approachable communication paired with technical precision is a hallmark of their work. When professional technicians break down otherwise intimidating concepts, dissatisfaction and confusion give way to empowerment and comfort. Homeowners who take the time to understand their HVAC system—supported by the kind of technical guidance Red Rock Mechanical provides—are better equipped to spot early warning signs, avoid costly breakdowns, and enjoy year-round peace of mind.

The Confidence to Act: Recognizing and Responding to HVAC Cycle Issues

Another Vermont resident recently recounted the difference that expert, friendly intervention can make:

“Our heat pump kept freezing up. The team from Red Rock Mechanical diagnosed a low-refrigerant issue within minutes and walked us through how the cycle works. Exceptional service and incredibly knowledgeable technicians.”

These stories underscore a crucial truth: when homeowners are included in the diagnostic process—and educated on why symptoms occur—they become more proactive in maintenance, quicker to act when trouble arises, and much more confident in their choices. Red Rock Mechanical’s ongoing commitment to demystifying the refrigeration cycle means every service call is an opportunity for customers to learn, as well as to restore comfort.

A Homeowner’s Best Tool: Knowledge of the HVAC Refrigeration Cycle

In a region where comfort systems are pushed to their limits, there is immense value in understanding the HVAC refrigeration cycle. From recognizing early warning signs to communicating effectively with technicians, informed homeowners can avoid major disruptions and extend the lifespan of their equipment. The expertise and clarity provided by Red Rock Mechanical, LLC—crafted through decades of service in Vermont’s tough climate—give residents both the tools and the confidence to keep their homes safe, efficient, and comfortable. Ultimately, the difference between enduring another sweltering summer or frosty winter in frustration, and enjoying reliable comfort, may simply be understanding how the refrigeration cycle works and partnering with knowledgeable, communicative professionals.

Contact the Experts at Red Rock Mechanical, LLC

If you’d like to learn more about how HVAC system knowledge and proper care can benefit your home’s comfort and efficiency, contact the team at Red Rock Mechanical, LLC.

📍 Address: 339 Red Rock Rd, Colchester, VT 05446, USA

📞 Phone: +1 802-893-9992

🌐 Website: https://www.redrockmechanical.net/

Red Rock Mechanical, LLC Location and 24/7 Availability

🕒 Hours of Operation:

📅 Monday: Open 24 hours

📅 Tuesday: Open 24 hours

📅 Wednesday: Open 24 hours

📅 Thursday: Open 24 hours

📅 Friday: Open 24 hours

📅 Saturday: Open 24 hours

📅 Sunday: Open 24 hours

Add Row

Add Row  Add

Add

Write A Comment